Getting Back to Build Basics with Keino Sasaki

HOW METAL MOVES ... AND HOW YOU CAN MOVE METAL

Some might call it a test of metal. A course designed to put you back in touch with artisan skills, working with your hands, and mastering tools that have been used to shape metal for many decades.

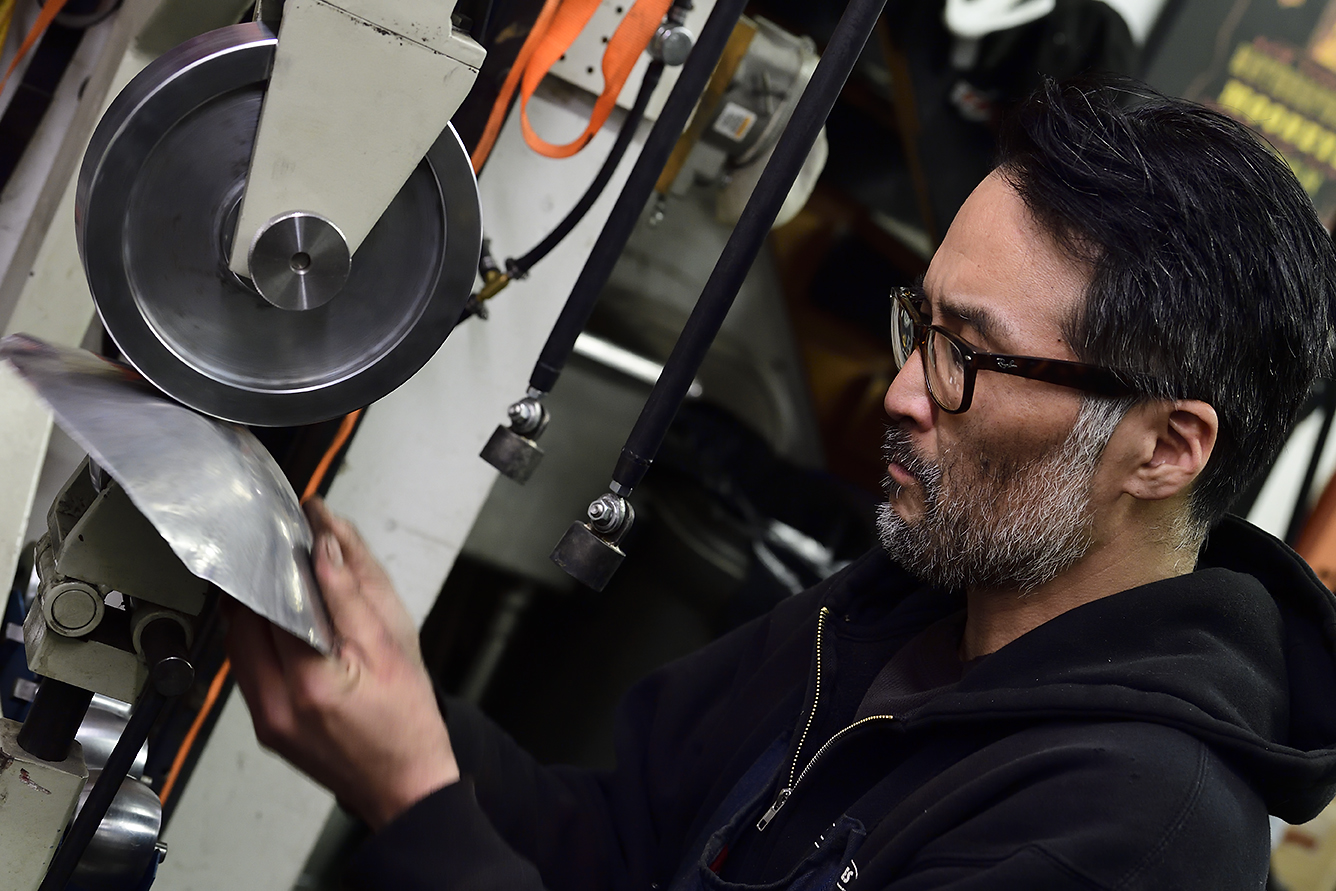

Sheers, snips, mallets, hammers, dollies, English wheels … basic tools and techniques are at the heart of a course being taught at Red Hook-based Keino Cycles, by owner, builder, Indian Larry disciple and Brooklyn Invitational co-director Keinosuke ‘Keino’ Sasaki.

Sheers, snips, mallets, hammers, dollies, English wheels … basic tools and techniques are at the heart of a course being taught at Red Hook-based Keino Cycles, by owner, builder, Indian Larry disciple and Brooklyn Invitational co-director Keinosuke ‘Keino’ Sasaki.

“Basically, this is a class I wish I had (had) a chance to attend when I started to shape metal,” says Keino, whose shop is famous for handcrafted motorcycles such as the recent Vincent custom collaboration with Stephen Pate dubbed ‘Widow Jane’.

“There are so many mass-produced replacement and ‘uniquely styled’ gas tanks and fenders … some are good quality … others are not. But some people want more than store-bought products to meet their unique vision. You can turn your ideas into a shape with sheet metal shaping skills.”

Sheet Metal Shaping Basics is offered once a month to give aspiring builders and modders an alternative to the aftermarket parts industry, and a better understanding of the patience and skill involved in producing hand-crafted parts. Classes are limited to six people, allowing more hands-on experience for participants, and more one-on-one time with the instructor. The 9-to-5 session covers a wide range of tools as well as a 20-page textbook written by Keino himself.

There are so many mass-produced replacement and ‘uniquely styled’ gas tanks and fenders … some are good quality … others are not. But some people want more than store-bought products to meet their unique vision. You can turn your ideas into a shape with sheet metal shaping skills.

Skills taught include stretching and shrinking metal techniques as well as finishing methods … planishing with hammers and dollies.

“The main elements of sheet metal shaping are stretch and shrink,” Keino says. “There are so many tricks and approaches to shape metal. In this one-day class, I focus on basic techniques of stretch and shrink with basic tools and equipment that are affordable for DIY guys, and beginners.”

The class sees students working with steel and aluminum on three learning projects – two simple bowls and a teardrop-shape form – all geared to teach a specific skill set.

Each workstation is manned by two students and consists of a planishing hammer – for surface finishing, a set of body hammers, two sets of mallets & a shot bag, and a pair of aviation snips.

“I believe the best way for you to learn a skill is (by) spending time doing it,” Keino says, adding practice will be guided by simple principles he’s developed through more than 16 years of experience.

“A gas tank, a fender, a fairing … they’re all a combination of the basic techniques with basic tools,” he says.

“I use pretty expensive equipment now, but I started out with all these basic tools, practiced, made mistakes, and started again,” he says. “My old mentor and boss, Indian Larry, gave me a book on Christmas, (a) sheet metal ‘how to book’ … though Larry wasn’t experienced in sheet metal. Around that time, I bought a cheap used English wheel and basic tools through someone I knew. I started doing, bought (a) bunch of how-to videos, and met and asked (advice from) a few other people along the way. I am still learning (and) constantly practicing.”

Keino still has the very first tank he ever shaped and built, stored at his current shop as a reminder of his beginnings.

“What I learned from (that)? I sucked … but also the satisfaction of making (it).”

Since leaving the Indian Larry Legacy and then partner Paul Cox, Keino has continued to produce memorable bikes highlighting his specialties – motor configuration, frame work and sheet metal – with Keino Cycles giving him “more freedom to be creative.”

Keino — Rahoul Ghose

I use pretty expensive equipment now, but I started out with all these basic tools, practiced, made mistakes, and started again. My old mentor and boss, Indian Larry, gave me a book on Christmas, (a) sheet metal ‘how to book’ … though Larry wasn’t experienced in sheet metal. Around that time, I bought a cheap used English wheel and basic tools through someone I knew. I started doing, bought (a) bunch of how-to videos, and met and asked (advice from) a few other people along the way. I am still learning (and) constantly practicing.

There’s a Zen about Keino and his workshop that comes from an artist – in Keino’s case a very modest artist – who enjoys what he’s doing.

“If I have a talent I think (it’s) patience … nothing happens overnight … taking a class, watching videos, buying expensive equipment doesn’t make you a master craftsman. You have to do it ... doing it, whatever you do, makes you better. This is my calling … I do enjoy not only shaping metal, but grinding metal … welding metal."

The classes also come at a time when Keino has been focusing more heavily on sheet metal work in his builds … on the lifts currently – a Yamaha XJR1300, a Vincent and a Harley.

“Traditional skills are important … as much as advanced mass production techniques. I do enjoy the affordability and availability of mass-produced products on some stuff. But I hope that my class will help people understand how much skill and patience is involved, how easy/hard it can be, and also (help them to) appreciate skilled trades.”

Case in point is the aforementioned Norton Keino is currently working on.

“I just like making things out of nothing. It’s a really satisfying feeling … first you have a vision and then you figure out how to go at it … sometimes you make a mistake, but after a few tries it looks like the shape you want. It’s not only sheet metal, it’s any kind of fabrication involving motorcycles.”

The Norton bodywork – tank, fairing and seat cowl – have an almost sensuous flow to them.

The tank started off as a sketch, then pieces of sheet metal, shaped and seamlessly welded together.

“It took about two to three weeks from planning to making the pattern for the frame, shaping the metal, welding and planishing. It involves so many processes.”

If you are interested in taking Sheet Metal Shaping Basics, you can reserve a spot at keinocycles.com. The next courses – Saturday, March 25 and Sunday, March 26 – still have spots available.

Cost is $400 for the day, with $150 required to lock down your place, and the remainder due on class day. Lunch is included. Use the code 'NYCMotorcyclist' to get $50 off.

An intermediate level course (Level 2) is a future possibility if there’s demand, Keino says. Also notable, once better weather descends on the city, classes will be less available. Summer sees the Keino Cycles shop full of bikes being worked on, leaving free space at a premium.

KEINO — Evan Owen Dennis

Leave a Comment